In our ongoing exploration of the metaverse’s potential impact on the aviation industry, we embarked on an intriguing analysis, employing a “scenario-based approach” to envision the future integration of metaverse technologies within air travel.

Here is a quick reminder: When saying “metaverse,” we talk about the convergence of our physical and virtual realities powered by:

- Immersion: Utilizing immersive technologies such as Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR) alongside their corresponding devices, it crafts a hybrid reality that intertwines physical and digital dimensions.

- Ownership and Exchange of Digital Assets: The metaverse also enables the capability to possess and transact digital and virtual assets within these immersive spaces, facilitating a unique economy of virtual items and experiences.

Our collaborative effort, pooling insights from industry leaders at Airbus, Bauhaus Luftfahrt, and our team here at the Lufthansa Innovation Hub, has led us to formulate four distinct scenarios predicting the evolution of the metaverse in aviation over the next decade until 2035.

Each scenario is crafted to reflect varying degrees of consumer adoption and metaverse consolidation, setting the stage for a range of potential futures.

Scenario #2: “The B2B2C Aviationverse”

After exploring the “Golden Islands” scenario in the previous chapter of our aviation metaverse content series, we now turn our attention to the second potential scenario: “The B2B2C Aviationverse.”

This scenario imagines a future where consumer adoption of metaverse technologies remains relatively low, yet a singular, integrated metaverse infrastructure in aviation has successfully emerged.

How so? An alliance of OEMs, suppliers, and airlines have co-developed a metaverse platform to jointly develop industrial use cases along the aviation supply chain.

To dive deeper into this possible future, let’s examine what characterizes this scenario.

1. Cost, Inconvenience, and Discomfort Limit Accessibility

Similar to the “Golden Islands” scenario, this potential future anticipates low consumer adoption of metaverse devices and applications. In the Golden Islands scenario, the cost of these devices (currently ranging from hundreds to thousands of dollars) is a major deterrent.

However, aside from cost, several other points can limit consumer adoption. For instance, the inconvenience of wearing devices like headsets—think permanent ski goggles attached to your face—and the feeling of discomfort often associated with virtual reality. This discomfort is often due to “VR sickness” or “cybersickness,” conditions characterized by symptoms like disorientation, nausea, and dizziness that can kick in after just 10-15 minutes of use. Studies suggest that between 60-95% of users experience some degree of these symptoms, with severe cases affecting up to 13% of users, compelling them to remove the VR headset and abandon the experience.

The severity of cybersickness varies based on several factors: the quality of the visual experience and the headset, the dynamic nature of the experience (whether users are on a virtual rollercoaster versus a static scenic viewpoint), and individual differences such as age, gender, and posture. Beyond cybersickness, the physical strain of wearing heavy goggles for extended periods can lead to headaches, neck pain, dry eyes, and redness—issues frequently reported by users of even high-priced devices like the Apple Vision Pro.

In short, the unnatural experience of wearing computer devices on one’s head is assumed to be a significant barrier in this scenario, severely limiting widespread consumer adoption of metaverse access technologies, particularly headsets.

2. One Shared and Interoperable Space

Despite potential discomfort limiting mainstream consumer adoption, the technological evolution of the metaverse, particularly in industrial applications where comfort isn’t a primary concern, is expected to continue advancing. In the B2B2C Aviationverse scenario, we envision very active collaboration among aviation stakeholders to construct an open and interoperable metaverse platform.

This platform, a “Metaverse Aviation Workbench,” would be collaboratively developed and maintained by an alliance of aviation OEMs, suppliers, and airlines. It is conceived as a shared virtual space where collaborative engineering and design activities along the aviation value chain can occur. This virtual workbench would enable stakeholders to work together seamlessly from various global locations and adhere to the high safety standards in aviation while fostering innovation and efficiency in developing new aircraft designs, manufacturing processes, and maintenance techniques.

While the intricacies of building such a comprehensive virtual system are complex (and could indeed fill an entire article on its own), it’s imagined that this platform would operate under a unified technology standard. It would integrate various underlying technologies, such as

- Digital twins are virtual replicas of physical objects, environments, or workflows that can be connected to data streams coming from sensors at the actual object, environment, or workflow. This data, combined with the virtual twin, can be used to model and forecast how the physical asset could react to different situations.

- IoT, or the “Internet of Things,” is a term used to describe a digital network between devices with sensors, like those infusing digital twins with data. This network processes and exchanges data between devices.

- Artificial intelligence and Machine Learning are pivotal technologies that help manage and utilize large amounts of data.

- Blockchain and Web3 can be used to track assets like aircraft parts, software or hardware development, maintenance activities, quality management checks, or certifications. Moreover, a blockchain-based infrastructure for web services (aka Web3) could help boost the standardization and interoperability of applications and use cases. That said, currently, these use cases are largely experimental.

These technologies are already capable of supporting various aspects of aircraft manufacturing, engineering, and maintenance, making them ideal for this advanced collaborative environment.

Interestingly, as we will learn shortly, this collaborative model is already beginning to emerge.

The Metaverse Transforming Industrial Applications

Observing current applications of immersive technologies—including digital twins, 3D modeling, and virtual simulations—it becomes evident that the proliferation of a metaverse for industrial purposes is not just a possibility but an emerging reality.

Today, we see these metaverse-defining technologies applied across the entire industrial value chain, from product design and manufacturing to engineering, maintenance, and training processes. According to ABI Research’s 2022 estimates, the industrial metaverse sector is already valued at close to $20 billion and could grow to a $100 billion market by 2030.

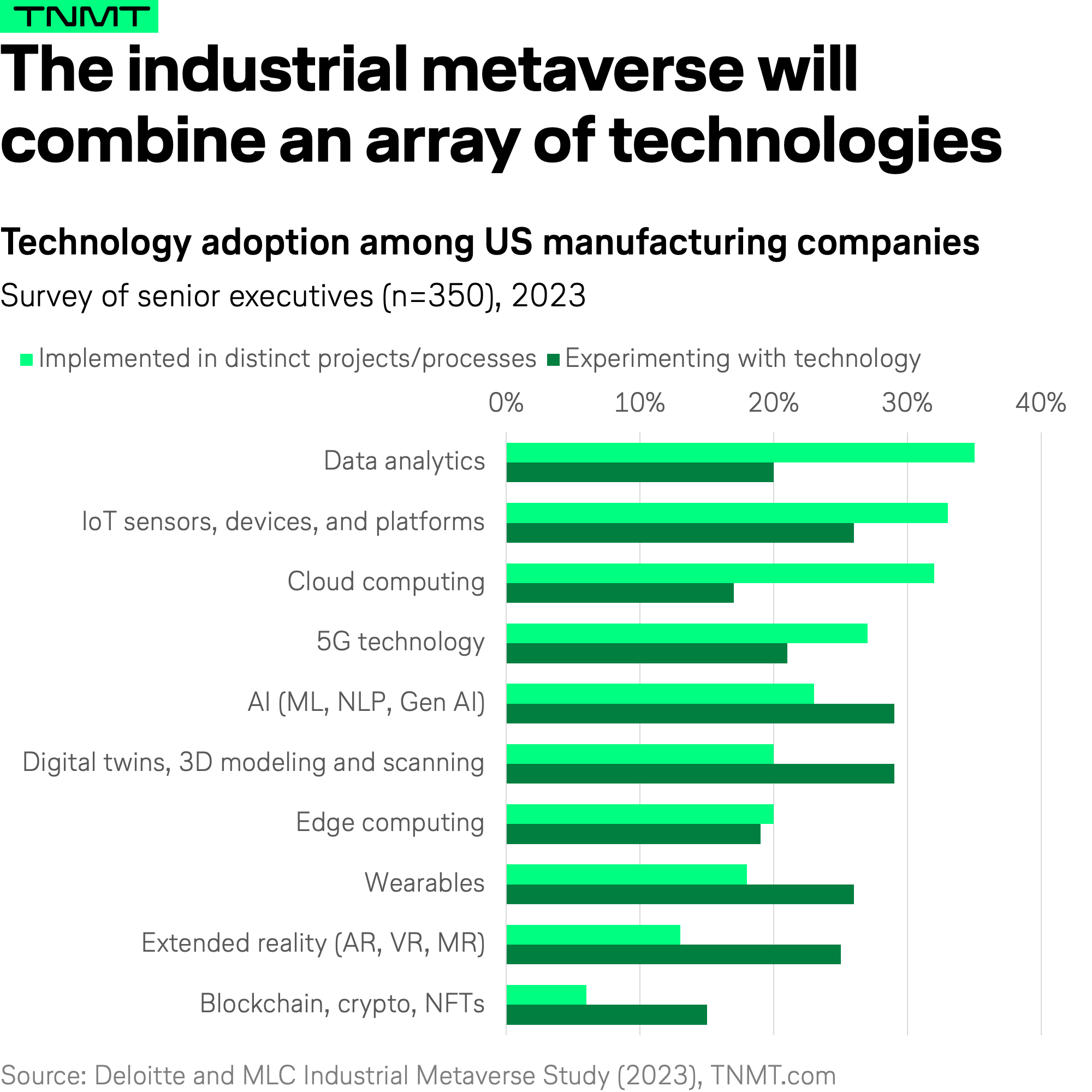

However, these “metaverse technologies” are predominantly used within isolated platforms and applications. Recent surveys show that 20-30% of US manufacturers have already implemented individual immersive technologies like digital twins and 3D scanning, with nearly 30% experimenting with new projects involving extended realities.

Long story short: The consolidation of these systems into a single integrated and interoperable platform could dramatically amplify transformational benefits across industries.

Major tech companies, such as Nvidia, are already paving the way toward creating holistic standards for immersive design in the industrial sector.

- NVIDIA launched its Omniverse platform in 2020. It was initially designed for collaborative 3D computer graphics and simulations across various fields, such as game design, architecture, and engineering. It has since expanded to include cloud services and AI-powered features, incorporating Generative AI for developers.

- Crucially, NVIDIA introduced the Universal Scene Description (OpenUSD) standard, which offers a suite of connectors to various 3D design formats, facilitating application across diverse industries. Companies like BMW Group, Siemens, and Foxconn and Innodisk are developing use cases on this platform.

We are seeing similar movements in verticals like automotive, where several automakers are actively exploring digital twins and pairing them with other immersive technologies.

- Audi, for example, utilizes virtual reality coupled with digital twins for assembly line planning.

- Renault, on the other hand, has launched an industrial metaverse platform hosting its entire supply chain data to monitor production sites effectively.

Even in the consumer goods space, category leaders like Procter & Gamble and Unilever are leveraging immersive technologies to optimize production processes, showcasing the wide applicability of these tools beyond traditional tech and manufacturing sectors.

However, aviation is an industry with exceptionally stringent safety and security requirements, affecting every aspect of the air transport value chain. Consequently, a platform relevant to aviation will need to adhere to the unique requirements and processes required by various industry stakeholders. Establishing a shared industrial framework will likely require a high degree of collaboration from the get-go.

Implications for Future Aviation

As we witness the rapid emergence of immersive technologies across various industries, it’s no surprise that aviation is deeply engaged with this trend as well.

In fact, our sector has long embraced immersive technology, experimenting with a range of applications spearheaded by industry leaders. Despite the broad adoption similar to other sectors, the use of these technologies in aviation is often fragmented. Different aviation players utilize varying platforms, standards, and procedures.

However, the accumulated expertise in these technologies positions aviation companies as potential “fast followers” who could swiftly adopt and benefit from a unified industrial metaverse. This metaverse would feature standardized and collaborative virtual environments, enhancing efficiency and innovation across the sector.

Key areas within aviation currently already under exploration with immersive technologies include:

1. Virtual Training: Setting the New Standard in Aviation

Digital simulations for training aviation professionals, from pilots to cabin crew and engineers, have long been a cornerstone of the industry. However, the integration of Virtual Reality (VR) has taken these trainings to unprecedented levels of efficacy and immersion.

Leading airlines and aerospace companies are now using VR as the standard training modality across various functions:

- Rolls-Royce and Qatar Airways began leveraging VR to train engineers as early as 2019, showcasing early adoption of immersive learning technologies in complex aircraft maintenance.

- Delta Airlines partnered with Futurus and ArborXR to revolutionize de-icing training for airplane technicians. This VR training enabled the airline to train over 150 technicians in a single day—a significant enhancement compared to the traditional capacity of training three technicians per day. This program was notably expanded in 2024, emphasizing the scalability and efficiency of VR applications.

- In 2023, Emirates introduced a comprehensive XR platform, also for training and collaboration, available to all its employees. This platform fosters a collaborative environment for sharing knowledge and best practices across global operations.

- Our parent company, the Lufthansa Group, maintains a dedicated division for the creation and management of VR trainings, Lufthansa Aviation Training. This division collaborates closely with industry leaders like Airbus to develop and refine VR training systems, ensuring they meet the high standards of aviation safety and efficiency.

2. Digital Twins and AR for Next-Gen Aviation Operations

Other immersive technologies, particularly digital twins and augmented reality (AR), have also been applied in the aviation sector for quite some time, specifically in order to enhance manufacturing, airline, and airport operations.

- Airbus and Boeing, along with OEMs like Rolls Royce, have integrated digital twins into their engineering workflows. These virtual replicas are used to analyze and predict aircraft engine performance under various conditions, facilitating a deeper understanding of operational efficiencies and maintenance needs.

- The Fraunhofer Institute has made significant advancements in maintenance, repair, and overhaul (MRO) applications by developing an AR solution tailored for aircraft technicians. This tool allows technicians to interact with virtual elements—such as instructions and technical tools—through gestures, voice, and gaze controls, streamlining the MRO process.

- Heathrow Airport has implemented a digital twin of its operations to enhance critical decision-making for runway scheduling. Similarly, Vancouver Airport has implemented a digital twin that uses historical and real-time data to enhance situational awareness and airport operations.

- More exploratory applications are also being pursued, such as using digital twins for the remote operation of eVTOL (electric Vertical Take-Off and Landing) aircraft. This forward-thinking approach could potentially transform how new aviation technologies are managed and controlled.

3. Pioneering Collaborative Research in Aerospace

In addition to these applications, we are also witnessing the first promising aviation attempts at collaborative research using immersive technologies. Launched in September 2022, the GENEX project, for example, is spearheaded by a consortium of 16 leading aerospace companies and research institutions across Europe.

GENEX is focused on developing a comprehensive suite of digital twins that span the entire lifecycle of an aircraft.

- This application is designed to enhance the precision and efficiency of aircraft manufacturing processes, enabling real-time adjustments and improvements.

- Aimed at monitoring the operational phase, it also assesses aircraft performance and maintenance needs during the service life of components.

- Additionally, specialized digital twins are being developed to streamline the maintenance, repair, and overhaul processes, particularly for composite materials, which are increasingly used in modern aircraft.

- And perhaps the most innovative of the suite, the cognitive digital twin integrates data from all other systems and tools. It analyzes this information to optimize the lifecycle management of composite components, enhancing decision-making processes and predictive maintenance strategies.

Envisioning the Next Decade in Aviation’s Metaverse Integration

As the use of immersive technology becomes increasingly prominent across the aviation value chain, the demand for a unified standard and platforms that facilitate sharing and collaboration will intensify.

Currently, the developmental use cases are highly fragmented across different corporations, each exploring these technologies in isolation.

However, collaboration is in the very DNA of the aviation industry. Whether it’s through the joint development of security standards and regulations or the collective process of gaining certification for new technologies and procedures, stakeholders across aviation are accustomed to working in concert. In this environment, a unified industrial metaverse could serve as an ideal platform to harmonize engineering, product development, and content standards across the sector.

Looking ahead, the B2B2C Aviatioverse scenario anticipates the emergence of several use cases within this industrial metaverse framework:

- Operational Optimization: Encouraging collaborative or at least shared development efforts could significantly enhance process efficiencies and product advancements, for instance, by improving augmented aircraft maintenance solutions.

- Collaborative Engineering: While digital twins, simulations, and immersive environments are already aiding aircraft design and development, the potential for collaborative platforms that connect OEMs, suppliers, and airlines remains largely untapped. Cabin design could be an interesting collaborative use case as it naturally requires alignment between the supplier and the airline.

- B2B2C Content Creation: Establishing a shared platform for developing virtual experiences and assets could standardize and elevate airline content across the industry. Imagine in-flight entertainment in an immersive 3D environment where you can virtually escape the cabin.

- B2B Service Enhancement: Leveraging immersive technologies for remote support can expand and scale support operations, significantly improving the customer service experience.

As we potentially venture into this envisioned future, the integration of a metaverse within the aviation sector promises to streamline operations and revolutionize how we conceive of and engage with air travel.